Count down the eight intelligent functions of photovoltaic inverters

逆变器在光伏电站(系统)中起着重要的作用。无人值守全自动光伏逆变器有多智能?今天我们来梳理一下。

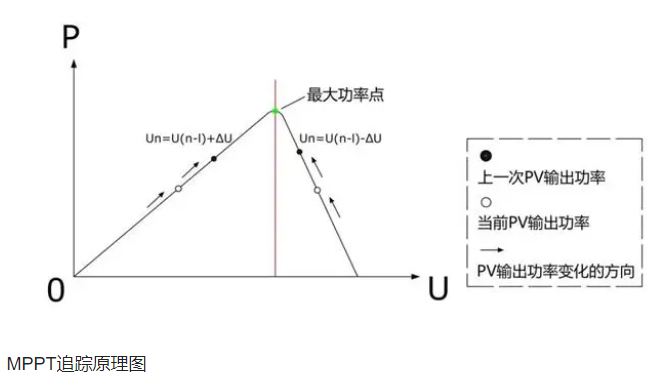

1、智能MPPT

MPPT(Maximum Power Point Tracker)技术是逆变器的核心关键技术,是指逆变器实时跟踪寻找元器件(方阵)最大输出功率的能力。光伏组件的输出功率受辐射、温度等多种因素的影响,不能一直输出标称的额定功率。增加发电量。

逆变器通过测量电流、电压、功率来判断当前工作点与峰值点的位置关系,智能调节工作点电压(或电流)使其更接近峰值功率点,从而光伏系统始终运行在功率点附近的峰值。

2、智能防孤岛

逆变器内置防孤岛(Anti-Islanding)保护电路,实时智能检测所接入电网的电压(V)和频率(f),并与预先设定的电压和频率进行比较实时,如检测到的实际值在合理范围内,说明逆变器工作正常;否则根据不同的测量值在相应的时间内切断电流,停止输出,报故障。

防孤岛和低压穿越本来就是矛盾的,但在一些无人值守电站或大型地面电站中,它们同时存在是有一定的必要性和理由的。国家标准的相关规定对反孤岛保护和低电压穿越的时间都有规定。当电网出现故障时,就会产生孤岛。此时,光伏系统只需要支撑1S左右的时间,等待电网恢复。如果2S后还没有恢复,则可以切掉。在此过程中,逆变器始终处于检测电网信息的状态。

3、智能字符串监控

随着技术的发展,逆变器在原有MPPT监控的基础上,已经实现了智能化的逐串监控。与MPPT监控相比,组串监控对电压、电流的监控准确到每一个支路串,用户可以清晰的看到每组串的实时运行数据。一个字符串的组成块个数不一致,一目了然。

4、智能IV曲线扫描诊断

光伏组件的I/V曲线是指光伏组件的输出电流与输出电压之间的一种对应关系,研究人员用曲线的形式来表示。

一旦元器件被遮挡、损坏或连接不良,元器件和串的I/V曲线将发生明显变化。

传统测试元器件的I/V曲线需要专门的测试工具(I/V曲线测试仪、辐照度计等设备),需要将待测组串从逆变器上拆下来,一根一根地测量。耗时长,延迟发电。

目前主流的高性能逆变器都已经具备了智能IV曲线扫描和诊断功能。主要实现原理如下:

(1) 测量组串开路电压Voc和短路电流Isc。

(2)测量最大功率点电压Vmpp和电流Impp,以及峰值功率Pmax。

⑶ 识别光伏组件/阵列缺陷、阴影遮挡、光伏组件粉尘损失、温升损失、功率衰减、串并联配置损失等。 5. 智能抗PID效应 光伏组件的PID(Potential Induced Degradation

)

效应指的是模块在长时间工作后性能会逐渐衰减的情况。PID效应的直接危害是大量电荷聚集在电池片表面,导致电池表面钝化,从而降低电池的填充因子(FF)、开路电压和短路电流。电池模块。降低太阳能电站的输出功率,减少发电量,减少光伏电站的收益。

PID效应在潮湿的环境中容易发生,其活跃程度与湿度大小呈正相关。同时,元件表面受电导率、酸度、碱度、带有离子的物体的污染程度也与衰减的发生有关。

目前主流元器件本身就具有抗PID作用的功能。另外,逆变器也可以增加这个功能。通过提高交流输出侧N线电压,间接提高PV负电压,使各逆变器PV负极对地电压接近0或略高于0电位,达到目的抑制 PID 效应。系统中的数据采集器与逆变器及外部抗PID模块连接通讯,自动采集逆变器负极状态信息,自动进行升降调节,从而实现智能抗PID功能。

6、智能风冷

散热是逆变器的一个重要问题。逆变器中集成了数千个电力电子元件。如果散热不好,会严重影响逆变器的输出能力和使用寿命。电子设备的10度定律是指温度每升高10℃,设备的寿命就会减少一半。目前,逆变器普遍采用智能风冷。逆变器外置高性能风扇,防护等级可达IP67。内置温度传感器和驱动电路实时监测器件温度并设置合适的阈值。当检测到温度超过阈值时,电路会自动驱动风扇运转。体温恢复正常后,

7、智能恢复并网

逆变器之所以能实现自动运行,是因为它具有智能恢复并网功能。电站能否正常运行取决于组串电压、电网电压、频率等诸多因素,逆变器可能因缺乏并网输出条件而出现待机或停机。一旦检测到运行情况正常,自检后(一般20s~5min)自动恢复并网输出,无需重新调试、重启等人工操作。

8、智能无功补偿

光伏逆变器在正常发电情况下只产生有功功率,但在实际应用场景中,尤其是工商业光伏自用应用场景中,负载消耗的功率不仅包括有功功率,还包括无功功率。结算时只收取有功电费,但同时考核功率因数。如果功率因数低于电网公司的要求,电网公司将收取惩罚性的功率调整费。为避免电力调节产生电费,工商业业主通常在负载端采用无功补偿装置,以保证功率因数达标。

但随着光伏电站投运,原有无功补偿装置的补偿能力不够,需要增购无功补偿装置。,智能调节功率因数,同时送出一部分无功进行智能无功补偿,可以帮助用户节省无功补偿装置的成本,也可以减少无功补偿装置在空载时的功率损耗.

从以上可以看出,逆变器确实是光伏电站的中枢和大脑。正是因为有了这些智能化功能的保障,光伏电站才能稳定运行,实现收益最大化。